Pandemic pressure and shifts in global markets have brought stiff challenges to the garment industry in Bangladesh. The sector will need to innovate, upgrade, and diversify, investing in flexibility, sustainability, worker welfare, and infrastructure.

As Bangladesh celebrates 50 years of independence, global attention is focused on the remarkable economic and social progress the country has achieved in recent decades. Even with the setbacks of the COVID-19 pandemic, the South Asian nation is on track to become a middle-income country within the next few years.

The ready-made garment (RMG) industry is a mainstay of this economic success story: Bangladesh is today one of the world’s largest garment exporters, with the RMG sector accounting for 84 percent of Bangladesh’s exports. This comes on the back of the sector’s rapid growth and modernization over the past decade—as well as the strides it has made in improving conditions for the country’s approximately four million garment workers. However, the pandemic has stalled the sector’s progress at a crucial moment, just as global shifts in fashion sourcing threaten Bangladesh’s position in industry supply chains.

Ten years ago, in 2011, we published our report, Bangladesh’s Ready-made Garments Landscape: The Challenge of Growth, for which we had collaborated with the Bangladesh German Chamber of Commerce and Industry. With this article we want to take stock of Bangladesh’s RMG sector—examining its growth to date, highlighting the big challenges it has navigated since then, and suggesting the transformative steps that are needed if the sector is to maintain and renew its economic vibrancy in the decade ahead. To support this stocktaking we have conducted a series of interviews with sourcing executives of leading global fashion brands and retailers.

From tragedy to transformation: Looking back at a decade of growth

The transformation of Bangladesh’s RMG sector over the past decade was catalyzed, in part, by a series of workplace tragedies that took the lives of more than 1,000 garment workers and made headlines around the world. The 2012 Tazreen factory fire and the 2013 Rana Plaza factory collapse highlighted massive problems in working conditions, led some international buyers to stop sourcing from Bangladesh, and prompted the United States to withdraw its preferential tariff agreement.

Today, Bangladesh’s RMG sector is a frontrunner in transparency regarding factory safety and value-chain responsibility, thanks to initiatives launched in the aftermath of the disasters—including the Accord on Fire and Building Safety in Bangladesh, the Alliance for Bangladesh Worker Safety, and the RMG Sustainability Council. These measures led to the closure of hundreds of unsafe, bottom-tier factories and the scaling-up of remediation activities in many others.

These steps helped restore Bangladesh’s attractiveness in the global apparel-sourcing market, leading to a decade of rapid growth. Ten years ago we forecasted a growth of 7 to 9 percent. Indeed RMG exports from Bangladesh more than doubled, from $14.6 billion in 2011 to $33.1 billion in 2019—a compound annual growth rate of 7 percent. (It is worth noting that this growth was within the range we forecast in our 2011 report, a collaboration with the Bangladesh German Chamber of Commerce and Industry.) Over this period, Bangladesh’s RMG industry increased its share of global garment exports from 4.7 to 6.7 percent. This is within the range we forecasted in our report, however it also shows that the country has not captured the full potential we had foreseen ten years ago.

There were signs of a slowdown, with the second half of 2019 showing negative growth compared to 2018. Then COVID-19 struck: in 2020, global lockdowns triggered order reductions, cancellations, payment delays, and renegotiation of terms. As the pandemic threatened the lives and livelihoods of Bangladeshi workers, many smaller, less well-funded factories closed their doors, and competition for smaller orders increased. The value of Bangladesh’s RMG exports fell by 17 percent in the first year of the pandemic, representing revenue losses of up to $5.6 billion.

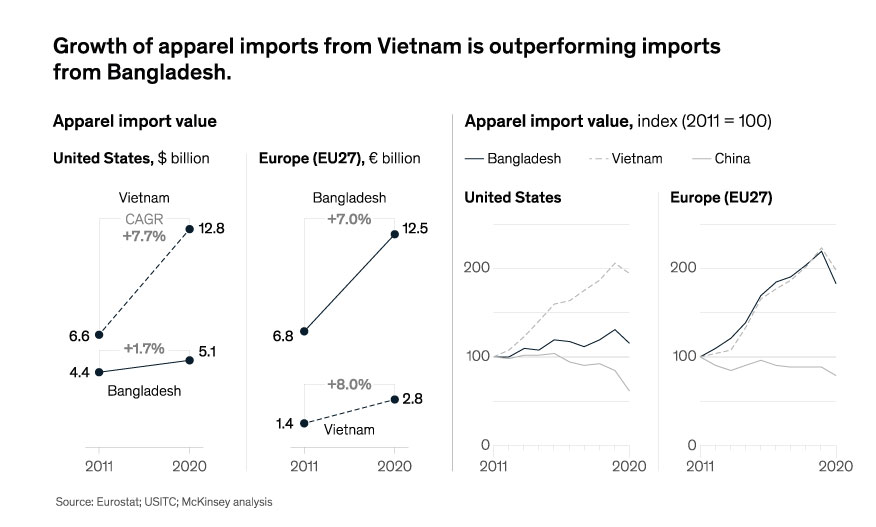

Our regular surveys of chief procurement officers (CPOs) in the fashion industry indicate that Bangladesh’s attractiveness as an apparel-sourcing destination remains potent—yet the country has faced increasing competition in recent years, which could compound the challenges of the pandemic. Although our 2019 CPO survey pointed to Bangladesh as the top global sourcing hotspot, Vietnam was close behind, and was the preferred sourcing country among US executives. Although comparable data for global exports in 2020 has not yet been published by the World Trade Organization, data from European and US imports indicate that Vietnam likely overtook Bangladesh in 2020—pushing Bangladesh’s RMG industry out of its position as the second-largest garment-exporting country in the world after China.

While Bangladesh’s RMG sector remains a strong exporter to Europe’s fashion industry, and has grown its market share significantly over the past decade, this trend may not continue: the new preferential trade agreement between the European Union (EU) and Vietnam, launched in August 2020, could well lead to apparel exports from Vietnam outperforming Bangladesh’s. Among US apparel importers, Vietnam has outpaced Bangladesh’s RMG industry for some time; in 2020, Vietnamese apparel imports into the US were worth 2.5 times those from Bangladesh. As buyers from the US move sourcing out of China, Vietnam is proving to be the biggest winner.

Tackling the big challenges

Over the past decade, Bangladesh’s RMG sector has made impressive progress in tackling the challenges of growth—particularly in diversifying customers and products, improving supplier and workforce performance, and strengthening compliance and sustainability. It is worth taking a closer look at the progress made in each of these areas, and considering what is required to build on it, while navigating the new challenges of the pandemic and the shifting global apparel-sourcing market.

A key strategy for the sector’s growth over the past decade has been to diversify customer countries and move to more complex products and value-added services. Bangladesh’s RMG sector has made progress in broadening its customer portfolio to manage risk and adapt to changing demand patterns in the global fashion market. However, Europe (62 percent of export value) and the US (18 percent of export value) remain Bangladesh’s RMG industry’s leading customer markets, although dependency on the US has decreased. There is room to increase exports to nontraditional markets, particularly as traditional markets are showing lower growth in apparel retail sales.

Several sourcing executives we spoke to for this article highlighted the progress that Bangladesh’s RMG sector is making in diversifying and upgrading its product offerings. For instance, there is now greater capacity to produce garments made from synthetic fibers; manufacture more complex products such as outerwear, tailored items, and lingerie; and provide new washes, prints, and laser finishings. Entry into these new segments has been supported by the changing rules of origin for preferential trade with the EU, allowing for the use of imported fabrics. There also has been some increase in vertical integration of the supply chain, with the result that more suppliers are now able to offer lead times below the standard 90 days.

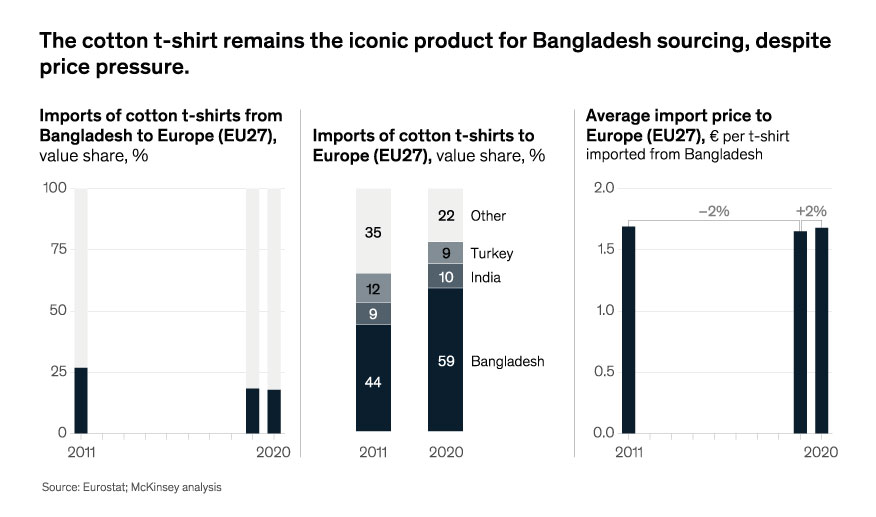

However, many of Bangladesh’s factories have not yet transitioned to providing these new offerings, and have shied away from the investment required to do so. The numbers show that T-shirts, trousers, and sweaters continue to dominate the country’s exports. In fact, Bangladesh’s top ten products accounted for more than 55 percent of the country’s export value of apparel to the EU in 2019 ; the iconic cotton T-shirt accounts for around one-fifth of the value of Bangladeshi garment exports to Europe. Consequently, Bangladesh’s garment industry is facing palpable price pressure in basic product categories.

The country’s RMG sector is by no means homogenous, however. Bangladesh’s advanced manufacturers are characterized by a high degree of entrepreneurship and strategic management; these firms have made investments in productivity improvement, digitization, automation, and sustainability, and they operate according to international best practices. In contrast, the small operators that make up the majority of the market typically focus on CMT; they tend to lack financial security and lag in management capability, and have also been hit hardest by the pandemic.

Encouragingly, sourcing executives of leading global apparel brands and retailers have partnered with their Bangladeshi suppliers, helping them to improve efficiency and sustainability.

A second major challenge facing the sector has been worker empowerment and the gender gap. Digitization of wage payment has increased, and there have been marked improvements in employment rights. Though the gender gap remains an issue, when it comes to opportunities for career progression from entry level. There is greater focus on gender diversity, as well as opportunities for upskilling and career progression today. However, progress has been slow, and COVID-19 has highlighted, and perhaps exacerbated, the precarious position of many Bangladeshi apparel workers.

Turning to compliance, factory and occupational safety, and transparency, the Bangladesh garment sector has shown enormous improvement. Factory buildings not only have become safer, Bangladesh now has more green garment factories than any other country, although these factories’ share of the country’s apparel exports remains low.

The sector’s participation in new initiatives regarding climate change and circularity have advanced the sustainability agenda, for example through the Circular Fashion Partnership, a multi-stakeholder initiative aiming to scale up recycling of production waste. Furthermore, more than 1,500 Bangladeshi companies are certified by the Global Organic Textile Standard, the second highest number in any country in the world.

Finally, infrastructure remains one of the biggest issues facing the RMG sector. For its apparel industry to prosper in the future, Bangladesh will need to strengthen transport, energy, and digitization infrastructure.

In the World Bank’s Logistics Performance Index, Bangladesh dropped from 79 in 2010 to 100 in 2018 in the overall ranking. By comparison, Vietnam improved its ranking from 53 to 39 over the same period. Several major infrastructure projects that are under development could significantly improve Bangladesh’s position. These include the Padma bridge, scheduled to open in 2021; and Bangladesh’s first deep-sea port, the Matabari development, which is expected to be functional by 2025, complete with a new container terminal.

Looking ahead: Transforming in a time of change

Bangladesh’s garment sector has every prospect of remaining one of the world’s largest RMG manufacturers, and continuing its impressive story of growth and improvement. However, the country’s apparel industry is facing headwinds, and will need to take decisive action in several areas if it is to prosper. It will need to rise to the challenges of competing without preferential trade access; meeting decreased demand from traditional customer markets; and making a fundamental shift toward a demand-driven and more sustainable sourcing model.

Some of the international buyers we spoke to believe the industry is not moving fast enough in this direction. Others are more positive: they feel that, given the resilience and adaptability Bangladesh’s manufacturers have shown in the past, the RMG industry will be able to navigate the necessary transformation, though structural changes will be inevitable.

As Bangladesh graduates from least-developed to middle-income country status in the next few years, preferential access to European and other markets is up for negotiation. Additional tariffs would be seriously disruptive for the RMG sector, but levelling the playing field with competing markets could also trigger a much-needed focus on productivity, as well as investment in digitization, automation, and sustainability.

Some global executives are reducing sourcing from Bangladesh, as their sourcing volume reaches a tipping point in their dependency and supply-chain risk on the country (which is further heightened by the pandemic), and owing to loss of competitiveness in some product categories. There is also an increased focus on nearshoring for greater flexibility and speed. That said, Bangladesh’s larger and more advanced suppliers may benefit from advances in flexibility, productivity, digitization, environmental sustainability, worker welfare, and innovation. One sourcing executive told us: “Speed is becoming more important, but only a minority of suppliers in Bangladesh understand that.” If they are to remain competitive, many suppliers will need to invest in upskilling, vertical integration, digitization, and automation to unlock speed and transparency.

Sustainability, too, is becoming ever more important, with increasing consumer demand for environmentally friendly products, and concerns about climate change and social justice. In 2020, Bangladesh ranked only 87 out of 115 countries in the World Economic Forum’s Energy Transition Index; transforming the Bangladesh RMG sector into a climate-neutral industry will be a major challenge, requiring enormous investment into renewable energy and the grid.

There will also be regulatory changes to contend with, especially in the EU. Suppliers will need to ramp up R&D and innovation: to drive product upgrading and diversification in areas such as technical materials and functional innovation; and to pursue sustainability by focusing on circularity, innovative fibers, and operational improvements.

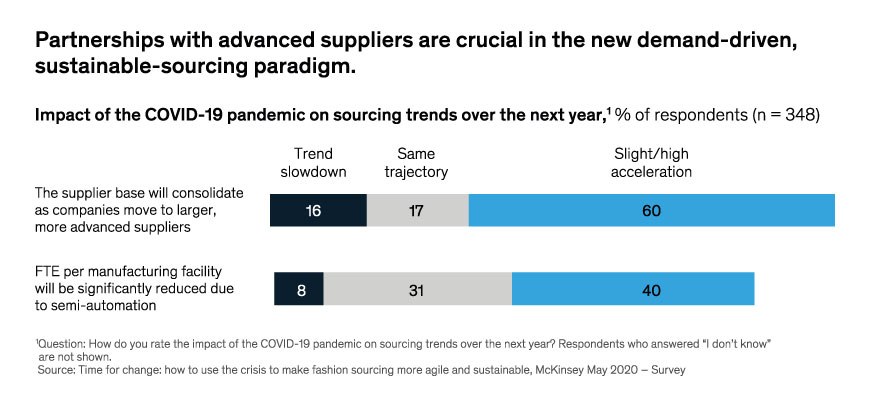

In our past sourcing surveys, consolidation towards more advanced suppliers to deliver on flexibility and sustainability gained traction.

Consolidation of Bangladesh-owned factories has been accelerated by COVID-19 (Exhibit 3), which has heightened the polarization of progressive suppliers and small enterprises—impacting the capacity of the whole industry to transform.

Some sourcing executives mentioned a shift of sourcing volumes towards foreign-owned factories in Bangladesh, especially for more complex or technical products and synthetics. They are also looking for suppliers who continuously invest in sustainability, worker welfare, and transparency.

Bangladesh’s government might benefit from recalibrating its strategies to attract foreign investors. An FDI, often from a multi-country corporations, brings global management and operational best practices, as well as R&D capability and funding. But Bangladesh’s RMG sector currently lags in FDI compared to its Asian peers. In Vietnam, for example, FDI-backed companies—from South Korea, Taiwan, Hong Kong, China, and elsewhere—account for around 70 percent of apparel exports.

Bangladesh’s RMG sector has achieved impressive growth and transformation over the past decade, overcoming significant obstacles along the way. Today, however, it faces a new set of challenges, amid a global pandemic and a shifting global apparel-sourcing market. In the years ahead, the industry will need to embrace a more holistic transformation, in partnership with manufacturers, international buyers, worker representatives, the government, and other stakeholders.

As international buyers navigate the rapidly changing environment, they are tasked to work with more advanced suppliers to develop demand-driven, more sustainable supply chains. To do so, they will need to build deeper, truly strategic partnerships, while pushing to overcome the past decades’ deflationary dynamics in global apparel retail markets.

Authors: Achim Berg and Karl-Hendrik Magnus are senior partners in McKinsey’s Frankfurt office, Harsh Chhaparia is a partner in the Gurugram office, and Saskia Hedrich is a senior expert in the Munich office.

Source: McKinsey